Engineering Plastics Business

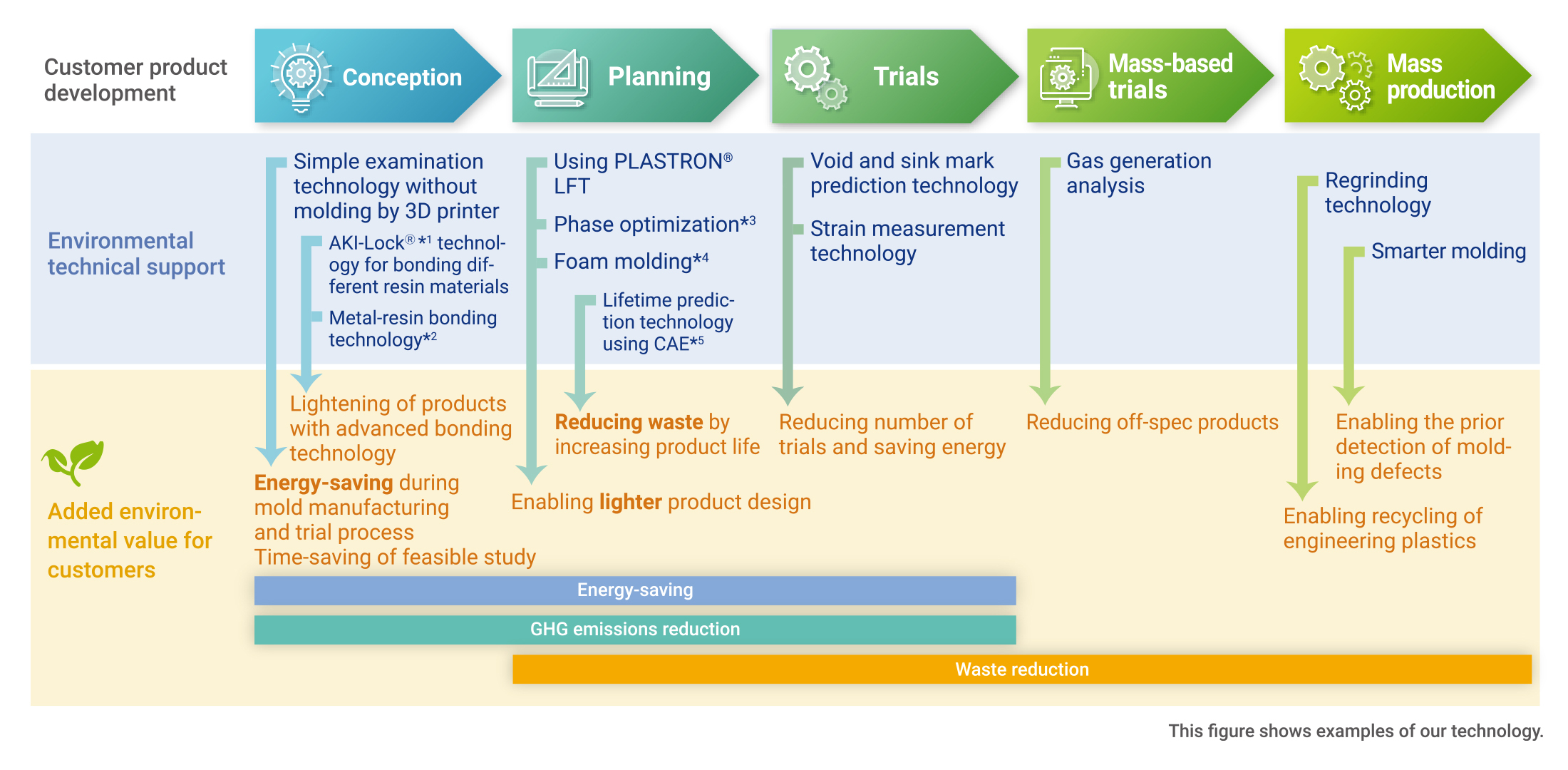

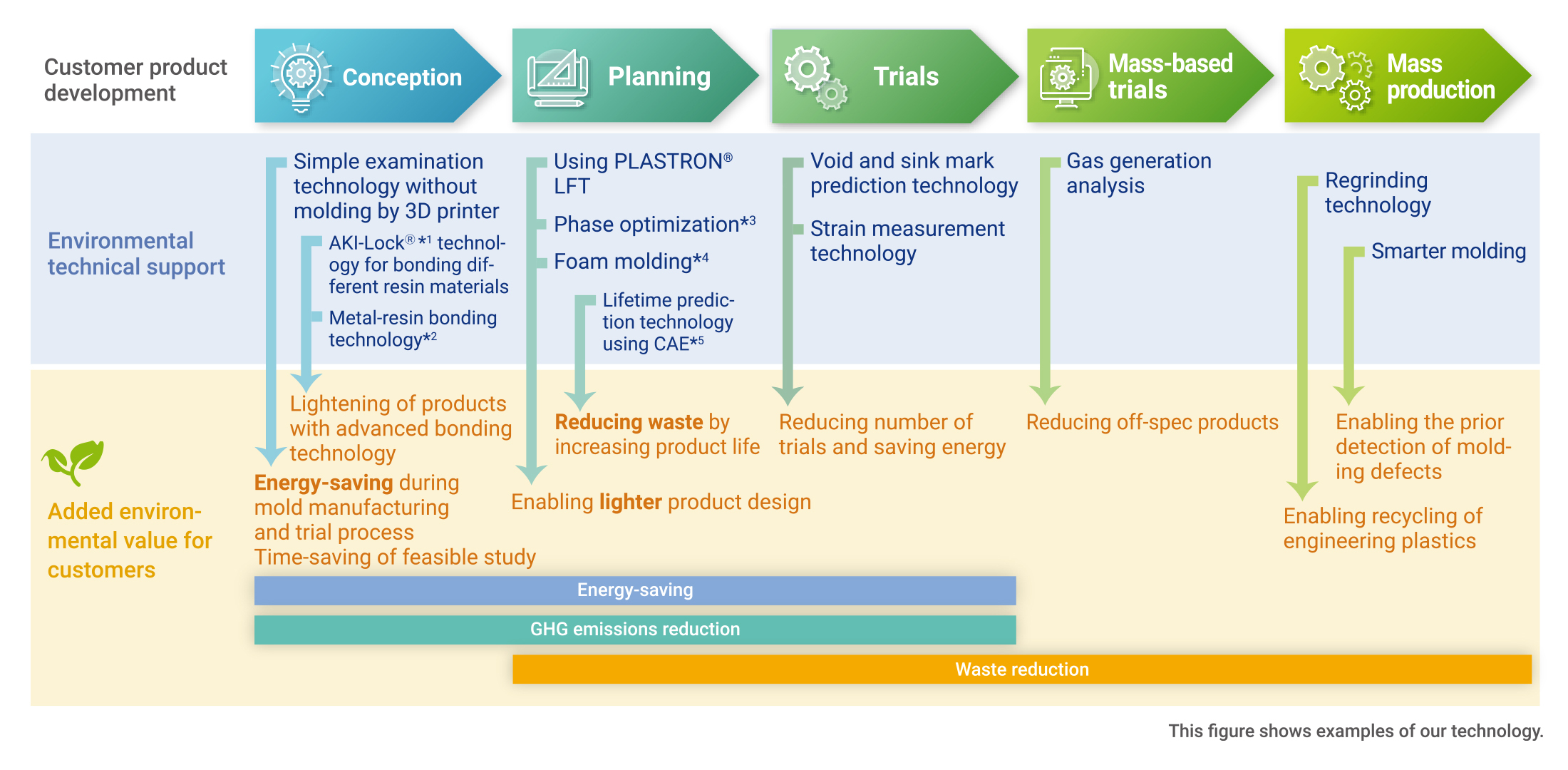

Proposing Every Approach to the Development of Products for Customers to Reduce their Environmental Impact

As a dedicated manufacturer of engineering plastics, Polyplastics has been providing comprehensive technical support throughout every stage of our customers’ product development—from initial concept to mass production. This includes assistance in material development, processing, and performance evaluation By leveraging this knowledge, we offer various forms of environmental technical support to help our customers reduce CO2 and waste at each stage of the development of their products.

- *1Our unique technology for bonding different materials

- *2Adhesive-free metal and resin bonding technology through insert molding of surface-treated metal

- *3Technology to extract rough shapes that maximize strength and rigidity within given design parameters

- *4Technology to reduce the weight of products by molding resins using foaming agents to create porous products

- *5Computer Aided Engineering

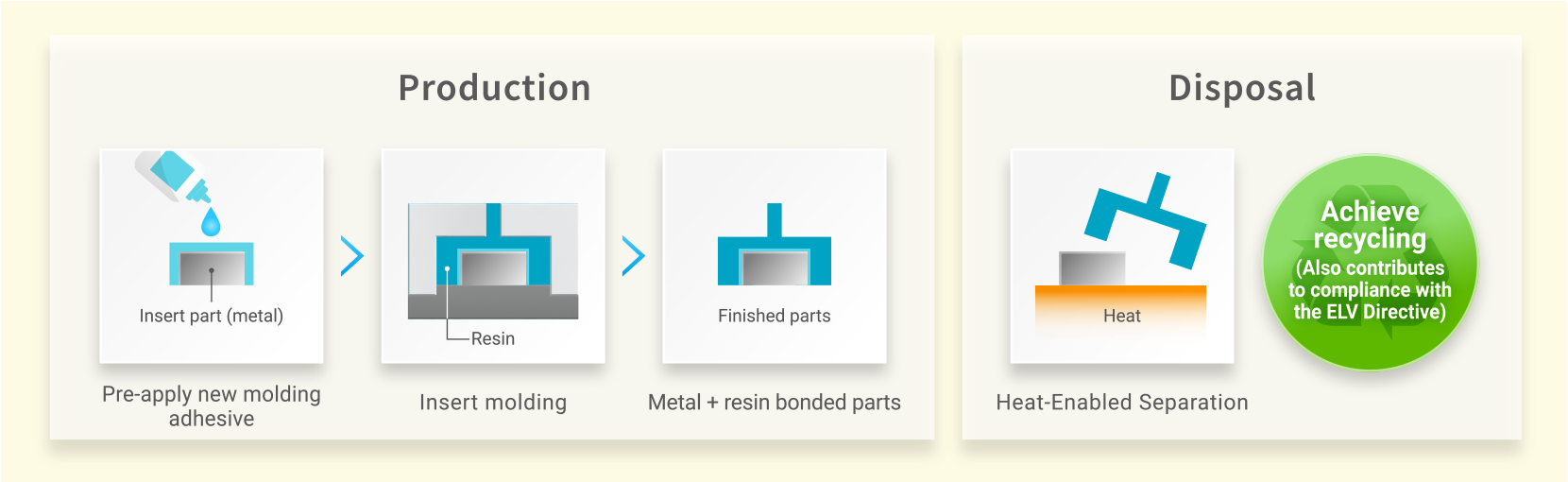

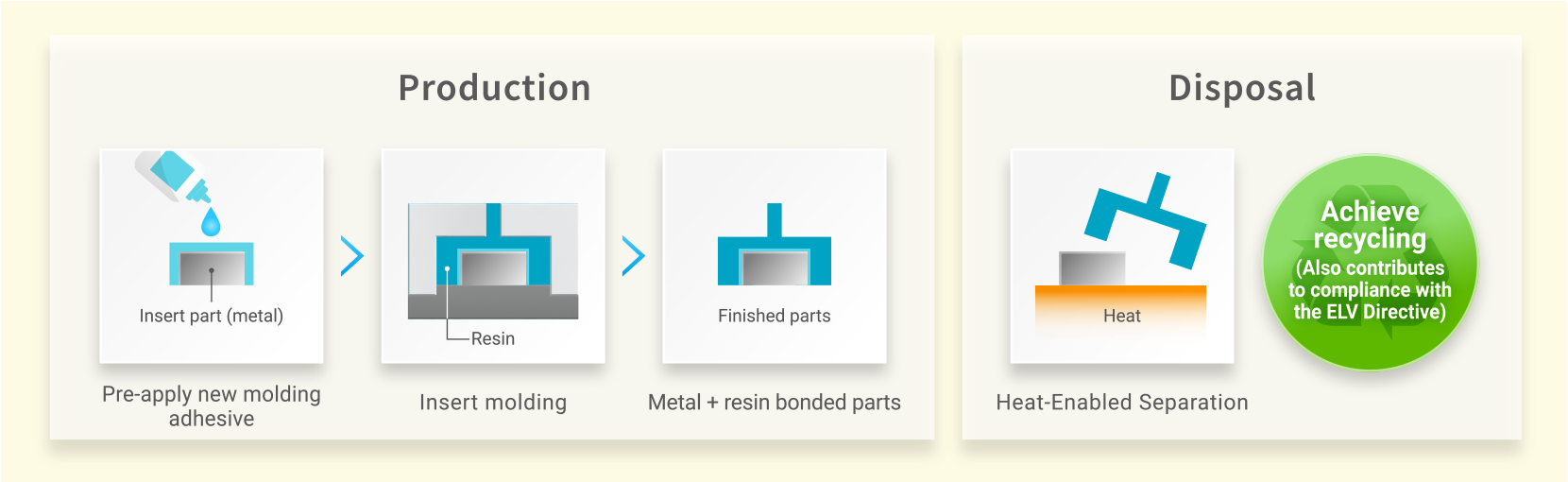

Innovative Molding Adhesion Meets EU ELV Demands

Generally, a bonding technique such as chemical or laser treatment is employed to bond metals and resins. However, while chemical treatment can expand the scope and number of pieces undergoing treatment at one time, it is time-consuming and also poses challenges for waste liquid disposal. On the other hand, laser treatment is cleaner, but may consume significant energy depending on the equipment used.

In seeking to address these challenges, we developed a bonding technology that utilizes a new molding adhesive in collaboration with an adhesive manufacturer. This technology improves airtightness in the interface between metal and resin after injection molding through the prior application of an adhesive to the metal to be bonded. While the metal to be bonded requires a short drying period for a short period of time after the application of the adhesive, molding under standard conditions is possible and no post-processing, such as heat curing, is needed.

As a result, no specialized skills are required, as the adhesive can be applied easily—enabling the standardization of operations. Additionally, by reducing the need for post-processing steps, this approach is expected to improve overall production efficiency.

The adhesive itself is based on thermoplastic technology, which allows it to soften sufficiently when heated, thereby weakening its bonding strength and enabling easy separation. Leveraging this characteristic, components that have been bonded can be readily detached, facilitating the reuse of resin parts. In the automotive sector, this technology is anticipated to contribute to material reuse initiatives, such as those outlined in the European ELV (End-of-Life Vehicle) regulations.

Timely Local Support for Material Development and Design

The share of the Chinese automotive market accounted for by EVs has been rising rapidly and stood at approximately 26% in 2024. In aiming to provide further technical support to satisfy customer needs in the booming EV market, electronic device market, and other such markets in China, we began working to locally conduct R&D on materials in China.

One of the key characteristics of local EV manufacturers in China is their remarkable speed in development, production, and market launch. While we had previously operated R&D sites only in Japan, we established a team for R&D activities in China in FY 2024 and put in place a system to develop grades that rapidly address customer needs. In order to increase the pace of the development of materials, we are using Shanghai Daicel Polymers’ production lines and otherwise leveraging our close ties with that company to develop materials that meet the needs of local EV manufacturers. By promoting the development of materials on a local basis, we can accommodate needs with far greater speed than we can with just the system we have in place now in Japan for the development of materials. Reducing transportation distances through the streamlining of logistics is also expected to substantially help reduce emissions of CO2.

In order to reinforce planning and development support in response to the rapidly changing needs of local customers, we are also focusing our efforts on in-house training aimed at raising the technical skills of local technical support staff members. By delivering prompt and accurate planning proposals and molding support, we want to help shorten development times for customers, extend the service life of parts, make parts more lightweight, and achieve these goals more effectively than ever.

In China, company efforts aimed at reducing their environmental impact are accelerating. We will continue to support the development of sustainable technologies for not just the EV sector but also local manufacturing companies.

Technical Support for Customers

On-line Support for Customer Product Development

We have established a free, membership-based on-line technical support service, “WEB@TSC®” that provides support 24 hours a day, 365 days a year. In addition to providing a variety of technical information, such as detailed information about physical properties, other product-related inquiries, requests for safety and export-related certificate issuance and other customer needs are meticulously handled. This easily accessible, Web-based service has been well-received among our customers.

Client Voice

- We are grateful for the flexible supply system and technical support we are receiving.

- The technical support page is professionally produced. We frequently consult it online in the course of operations as it provides answers to questions that we have.

- We are deeply grateful for your continued technical support, including the regular seminars and the opportunities for us to visit TSC.

- There are many opportunities for requesting surveys on contained chemical substances and the much greater speed at which reports are issued compared to other companies is truly helpful.

- We truly appreciate your prompt responses to our questions, which are always grounded in your extensive knowledge of engineering plastics and deep insights into industry trends.