Environment and Safety

GHG Reduction Targets for FY2030

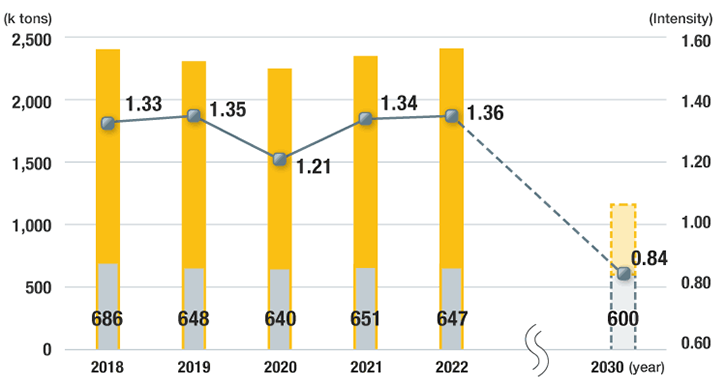

In line with the goal set by the Daicel Group of reducing GHG emissions (Scope 1 and 2) by 50% compared to 2018, the Polyplastics Group aims to reduce its GHG emissions intensity per unit of resin (includes CO2 derived from raw materials) by 46% compared to 2013.

Daicel Group

Total GHG

emissions(Scopes 1, 2)

50%

reduction(vs. 2018)

Polyplastics Group

PCF-focused

GHG emissions

intensity(including CO2 derived

from raw materials)

46%

reduction(vs. 2013)

FY2022 Performance and Mid-Term Targets

CO2Emissions Reduction

In FY2022, Polyplastics actively promoted energy-saving activities at every plant, for example, changing the ejector of the vacuum unit to a motor at the Kuantan Plant in Malaysia. On the other hand, emissions intensity slightly increased because the Daicel Group’s selfconsignment of electric power was suspended for about four months due to trouble.

We are planning large-scale growth investment toward 2030, and CO2 emissions are expected to increase accordingly, but we will realize thorough energy-saving through production and technological innovation as well as energy conversion. We will reduce emissions to the level in 2018 and aim to significantly reduce emission intensity.

Daicel Group total CO2 emissions (Scope 1, 2)

Mid-Term target

By 2030

Daicel Group

Total GHG emissions (Scope1,2)

50

% reduction (vs. 2018)

Industrial Waste Reduction

Target

under14.9%

Result

10.8%

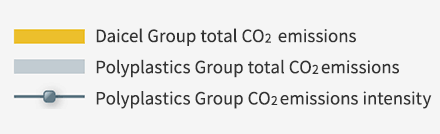

Dust from the dust collector of the compounding machine at the Kuantan Plant that had formerly been disposed of in landfills, has been used as a raw material for cement since FY2022. This resulted in a 6.5 point decrease compared with the previous year of the landfill and incineration without heat recovery rate to 10.8%. We will continue to actively work towards the achievement of zero-emissions for the group.

Until now, the landfill and incineration without heat recovery rate has been set as a management indicator, but starting in 2023, the Daicel Group set the recycling rate* as the new indicator.

- *Recycling rate = Amount recycled (including salable resources) / Total by-products and waste generated

Landfill and incineration without heat recovery rate

Mid-Term target

By 2030

Achieve zero-emissions for the group

(landfill and incineration without heat recovery rate under 1%)

By 2025

Group recycling rate

At least

97

%

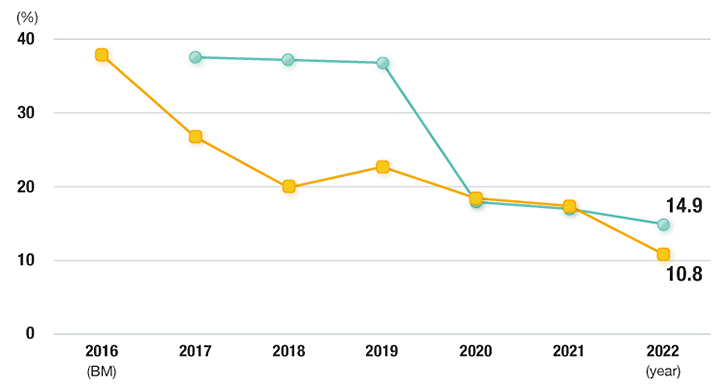

Reducing Emissions of Chemical Substances (PRTR Substances*1)

In FY2022, we completed repairs to the exhaust gas combustion facility, which had been shut down due to trouble that occurred in the previous year, and emissions of PRTR substances into the atmosphere were reduced by approximately 67% from the previous year.

In 2023, we will install “PRTR substance emission control combustion equipment”*2 in our major emission sources, and work toward our 2024 target of a 75% reduction in total emissions (Fuji Plant) compared to 2019 levels.

- *1Pollutant Release and Transfer Register

- *2Capable of reducing PRTR substance emissions by up to 95%

PRTR substance emissions (kg)

Mid-Term target

Total PRTR emissions

By 2023,

reduction of

50%

(Fuji Plant vs. 2019)

By 2024,

reduction of

75%

(Fuji Plant vs. 2019)

VOC

Establish VOC measurement methods and benchmarks

by FY2022